Essential safety reminders to protect your crews and your bottom line

Brush up on important safety reminders this Forklift Safety Day Forklifts are key to workplace productivity but introduce a variety

Brush up on important safety reminders this Forklift Safety Day Forklifts are key to workplace productivity but introduce a variety

Last month I started a series on the customer experience (the CX). To refresh your memory (or if you missed

A recruiting best practice to balance multiple hires and not lose the ever-important speed to hire Sometimes hiring is crazy

The Association of American Railroads (AAR) has reported U.S. rail traffic for the week ending May 15, 2021. For this

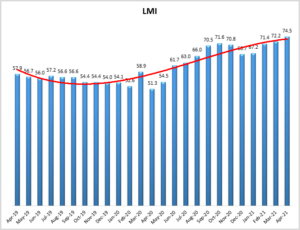

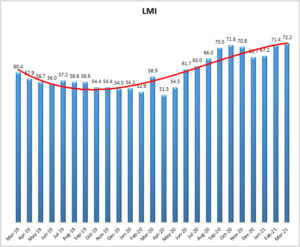

Growth is INCREASING AT AN INCREASING RATE for Inventory Levels, Inventory Costs, Warehousing Prices, Transportation Capacity, Transportation Utilization, and Transportation

Members of the International Warehouse Logistics Association (IWLA) recently elected Scott Mayfield, president & CAO Kenco Logistic Services, Chattanooga, Tenn.,

Pintsch Bubenzer USA will again deliver a presentation to the Association for Iron & Steel Technology (AIST) Crane Symposium. The

The National Forklift Safety Day (NFSD) sponsored by the Industrial Truck Association will again be virtual on Tuesday, June 8th.

The Canadian government continued its push this week to label plastic a “toxic” material, publishing an order-in-council in the Canada Gazette Part

The Women In Trucking Association (WIT), Truckstop.com, and Transportation Intermediaries Association (TIA) announced today Angela Eliacostas, president and founder of

The Association of American Railroads (AAR) has reported U.S. rail traffic for the week ending May 8, 2021. For this

Demand-driven by online spending, retailers restocking shelves An ongoing cargo boom largely driven by online purchases lifted the Port of

On this episode, I was joined by Senior Vice President at Lee & Associates, Justin Smith. Justin is also the

ProMatDX brought the manufacturing and supply chain industry together April 12 -16, with over 17,000 attendees learning, engaging, and discovering

The Equipment Leasing and Finance Association (ELFA) has awarded Bonnie Michael, Vice President Legal and Compliance USA for Volvo Financial

In this episode, I was joined by Nathan Perkins of CSG Partners who focuses on ESOP. This is the latest

LMI® at 72.2 Growth is INCREASING AT AN INCREASING RATE for Inventory Costs, Warehousing Utilization, Warehousing Prices, Transportation Prices Growth

The primary task in the distribution business is to care for the customer and meet their needs. This is an

As we enter the later stages of the Coronavirus pandemic, equipment companies in material handling and related industries are seeing

We have been hearing the word “TRANSITORY” coming out of DC a lot lately. Transitory this and Transitory that to