Fleet Team welcomes Marc Terwilliger as VP of Warehouse Systems

Fleet Team has announced the appointment of Marc Terwilliger as its new Vice President of Warehouse Systems. With almost two

Fleet Team has announced the appointment of Marc Terwilliger as its new Vice President of Warehouse Systems. With almost two

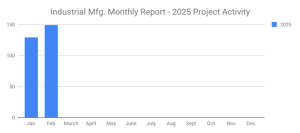

Industrial SalesLeads released its February 2025 report on planned capital project spending within the Industrial Manufacturing sector. The company monitors

I’m at a corporate conference about to give my 90-minute, customized, personalized talk. As I do with all my talks,

The United States is experiencing a severe skilled labor shortage and rising wage inflation. A growing body of evidence points

International logistics leader reports 10% net revenue gain year over year and in North America, strategic expansion drives revenue growth

The American Society of Safety Professionals (ASSP) just made the following statement regarding the confirmation of Secretary of Labor Lori

Mitsubishi Logisnext Americas has announced the recipient of their 21st Annual 2025 Cat® Lift Trucks Scholarship Program. This year’s $5,000 scholarship winner

Manufacturing technology orders totaled $357.3 million in January 2025, down 29.8% from December but up 5.7% from January 2024. While

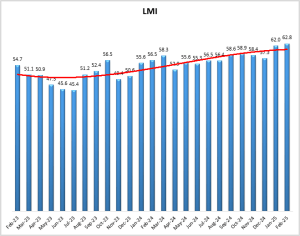

Growth is INCREASING AT AN INCREASING RATE for: Inventory Levels, Inventory Costs, Warehousing Utilization, Warehousing Prices, and Transportation Capacity. Growth

MHEDA has announced the winners of the prestigious 2025 MVP (Most Valuable Partner) and MVS (Most Valuable Supplier) Awards. These

Equipment Fleet and Working Capital Management Generate Strong Fourth Quarter Cash Flows as Pressured Volumes and Gross Margins on Equipment

The National Association of Wholesaler-Distributors (NAW) is one of America’s leading trade associations, representing the $8.2 trillion wholesale distribution industry.

PLASTICS president and CEO Matt Seaholm issued the following statement regarding the Trump Administration’s implementation of tariffs on Canada, Mexico,

The Women In Trucking Association (WIT) has announced Christine Iva Britton as its March 2025 Member of the Month. Britton

SAP and research consultancy Earth Action have launched “Shift into Gear,” a report urging the global industry to prepare for

The KION Group finished the financial year 2024 with consistent operating performance and strong financial results: With slightly improved revenue

Say there’s a new corporate initiative that your team needs to fully understand and embrace. You sit down with the team,

Carolina Handling has launched a Speakers Bureau featuring subject matter experts in all areas of material handling who are available to speak

Revenue Center Management has been the pivotal dealer Best Practice for over thirty years. Yet, why are so many dealers

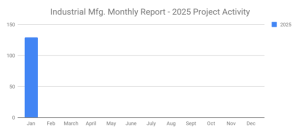

Industrial SalesLeads has announced the January 2025 results for the new planned capital project spending report for the Industrial Manufacturing