July 2020 U.S. Cutting Tool Orders down 8.5% from June 2020

July 2020 U.S. cutting tool consumption totaled $137.8 million, according to the U.S. Cutting Tool Institute (USCTI) and AMT –

July 2020 U.S. cutting tool consumption totaled $137.8 million, according to the U.S. Cutting Tool Institute (USCTI) and AMT –

In this episode of the podcast I was joined by Aldo McLean, Ph.D. at MODEX 2020. Aldo was walking by

The second quarter 2020 Sales History & Outlook Report (SHOR) released by the Power Transmission Distributors Association (PTDA) continues to indicate the

The Association of American Railroads (AAR) has reported U.S. rail traffic for the week ending September 12, 2020. For this

The Women In Trucking Association (WIT) announces today the full content line-up, with U.S. Secretary of Transportation Elaine Chao as a

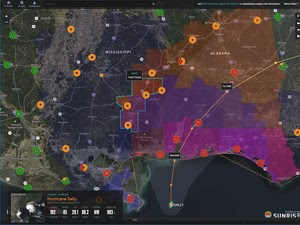

In an ideal world, the American Logistics Aid Network or ALAN would have plenty of time to focus all of

The British Industrial Truck Association (BITA) and Informa Markets – joint owners of IMHX, the UK’s largest logistics and supply

In this episode, I was joined by Mike Kinder who is the Co-Founder and CEO at Veryable. At Veryable they

The Women In Trucking Association (WIT) and Freightliner Trucks have announced the six finalists for the 2020 Influential Woman in

Today, the National Association of Wholesaler-Distributors (NAW), the largest distribution public policy association in the United States that represents wholesaler-distributors

The industry’s top experts and leading companies to participate RIA Robotics Week, the world’s largest virtual robotics show and conference,

There is a lot of uncertainty in the world today due to the COVID-19 pandemic. The team at MHI wants

The Security and Emergency Response Training Center (SERTC), an initiative of Transportation Technology Center, Inc. (TTCI) a subsidiary of the

In this episode, I am joined by Garry Bartecki of GB Financial services and also the cover story author of

When you work remotely—as so many people are doing in the age of COVID-19—there’s no natural boundary between your workday

The World of Finance at this moment is in a state of flux and will probably continue to be through

Here’s the rock, paper, scissors game of selling: The relationship is more powerful than the price. The relationship is more

Now, more than ever, our industry is trying to leverage their existing assets, and get more production out of fewer

MHI has announced that we have formalized a partnership with the Women in Manufacturing (WiM) association. With this partnership, MHI

WIT provides drivers with continued Espyr behavioral health support programs Women in Trucking Association (WIT), a nonprofit organization with the