Craig Salvalaggio appointed President of Applied Manufacturing Technologies

AMT has appointed Craig Salvalaggio, previously the Chief Operating Officer (COO), as its new president to lead the company’s growth

AMT has appointed Craig Salvalaggio, previously the Chief Operating Officer (COO), as its new president to lead the company’s growth

Leuze is placing its strong growth on a broader footing and has expanded its executive management. Xavier Hamers joined the

In a special panel episode of The New Warehouse, host Kevin Lawton welcomes industry experts to discuss Rajant’s revolutionary Kinetic

Ken Ramoutar, Chief Marketing Officer at Lucas Systems, joins The New Warehouse live from ProMat 2023. Lucas Systems is a

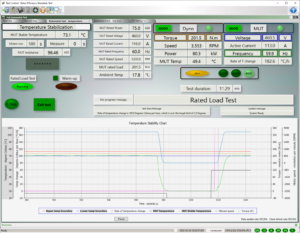

SAKOR Technologies Inc., a recognized leader in the area of high-performance dynamometer systems, announces the release of the DynoLAB™ GenV

CMO Dan Gilmore and CTO Mark Fralick of Softeon join The New Warehouse from ProMat 2023 to discuss the smart

The Tecsys connector will bring rapid, plug-and-play automation connectivity to robotics integration and warehouse automation solutions SVT Robotics, a provider

Vanderlande has announced the appointment of Andrew Manship as its next Chief Executive Officer (CEO). Andrew will take up the

NFI, a provider of North American supply chain solutions, announced that it has acquired SDR Distribution Services, a multichannel provider

Anil Varanasi, CEO and Co-Founder at Meter, joins The New Warehouse to discuss fast, secure, and reliable wireless connectivity for

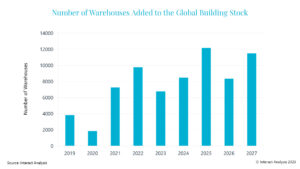

Warehouses added to the global building stock in 2023 down 35% compared with 2022. 26% of warehouses are expected to

René Schrama joins the executive leadership team to drive growth across the newly-combined organization Peak Technologies, a provider of digital

In this episode of The New Warehouse, Kevin sat down with Matt Fain, CEO of Pop.Capacity. Pop.Capacity is a digital

Brian Kirst, Chief Customer Officer, and Smitha Raphael, Chief Product and Delivery Officer at SnapFulfil join The New Warehouse to

Vinit Pednekar was recently promoted to Global Business Services Distribution Manager at SLB in Houston, Texas (US). Mr. Pednekar is

Tompkins Solutions has announced that Bob Toupin has joined the company as vice president of IT and supply chain technology.

Monadnock Paper Mills, a manufacturer of technical specialty and premium printing and packaging papers, announced that Stephen (Steve) Murphy has

The experts behind leading-edge cloud-based WMS software, SnapFulfil, have unveiled a breakthrough tech solution that orchestrates all automation devices and

Global logistics automation partner, Swisslog has announced that Mario D’Cruz has joined the company as Vice President of Strategy and

FusionPort™ and FusionPort Staging™ can handle up to 550 Bins per hour and feature improved ergonomics for greater productivity AutoStore™,