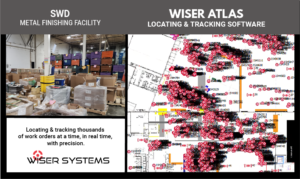

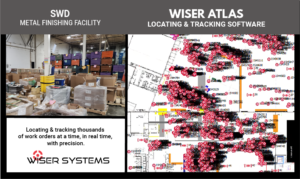

WISER Systems launches ATLAS: High Density, Enterprise-Wide Live Positioning Solution

The new WISER ATLAS provides revolutionary WISER Locator precision and ease of use scaled to thousands of work orders/assets across

The new WISER ATLAS provides revolutionary WISER Locator precision and ease of use scaled to thousands of work orders/assets across

On this episode, I was joined by the Director of E-commerce Operations & Fulfillment at Bonnie Plants, Sid Phelps. Bonnie

On this episode, I was joined by the Director of E-commerce Operations & Fulfillment at Bonnie Plants, Sid Phelps. Bonnie

EnerSys®, a global provider in stored energy solutions for industrial applications, will feature its family of virtually maintenance-free NexSys® battery

Siemens is presenting its latest solutions for smart and networked drive technology. By networking entire drive systems, machine and plant

In this episode, I was joined by two Ryan’s both from Phantom Auto. Ryan Chesterfield and Ryan Clifford both work

Three years of The New Warehouse Podcast! I can hardly believe it but I’m taking a moment to celebrate all

BeerBoard, a provider in technology and automated intelligence for the on-premise hospitality industry, announced that Florida Distributing Company (FDC), which

Synapse WMS to power warehouse operations for leading national third-party logistics provider Zethcon Corporation announces the selection of the company’s

On this episode, I was joined by the previous guest Justin Griffith of StayLinked. Justin is the CTO at StayLinked

Aptean, a global provider of mission-critical enterprise software solutions, announced the launch of Aptean EAM, an all-new, cloud-based enterprise asset

In this episode, I share my own knowledge from experience on how to increase your warehouse education. I have been

Unlike vendors with multiple WMS products, Softeon Warehouse Management System serves large, mid-level, and smaller operations across a fulfillment network

On this episode, I was joined by the US Regional Sales Director at JLT Mobile Computers, Glenn Lundgren. JLT Mobile

In this episode, I discuss something very important in the warehouse, cleaning! This is an incredibly important part of maintaining

WMS technology innovator, SnapFulfil, selects Brian Kirst a seasoned 3PL Executive for the role of US Vice President Sales &

Renowned Retail, CPG, and Supply Chain Veteran brings a world-class track record to a global provider of Internet of Things

Jeff Born has been named as the director of procurement and supply chain solutions overseeing North American activities for Tubelite Inc., Alumicor

The National Association of Wholesaler-Distributors (NAW) just announced the winners of its inaugural Distributors Deliver Award given at last week’s

Connected Industrial Mobility provider, SIERA.AI, announced the completion of a $6.8 million-dollar seed funding round. The funding round was supported